Innovative Strategies for Streamlining Complex Assembly Processes

In the rapidly evolving manufacturing sector, optimizing assembly processes has become a crucial factor in achieving operational success. With the advancement of technology and heightened customer demands, businesses are seeking new ways to enhance efficiency, minimize errors, and increase productivity.

Table of Contents

Leveraging a combination of advanced automation, strategic supply techniques, and visual control systems, manufacturers are redefining what’s possible on the shop floor.

For those requiring specialized solutions in electronics production, PCB assembly services Massachusetts offer access to skilled expertise and state-of-the-art methodologies for even the most complex projects.

The integration of innovative technologies, like autonomous robotics and algorithm-driven planning, enables manufacturers to meet demand with greater speed and reliability. Additionally, optimizing the timing and supply of components has proven to be an unconventional yet powerful tactic to enhance self-assembly operations, pushing the boundaries of traditional manufacturing wisdom.

By incorporating synthetic data solutions for quality control and leveraging the digital transformation, businesses can minimize training costs and maximize the value of real-time feedback in their assembly lines.

These innovative strategies not only help companies streamline their processes but also facilitate agile adaptation to market fluctuations, fostering a resilient approach to modern manufacturing challenges. Embracing a holistic suite of modern tools and methodologies paves the way for superior efficiency, scalability, and product consistency across all stages of the assembly lifecycle.

If you are interested in a deeper dive into manufacturing automation and trends in engineering advancements, refer to the comprehensive insights available from McKinsey’s Future of Manufacturing analysis.

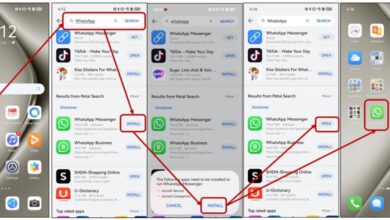

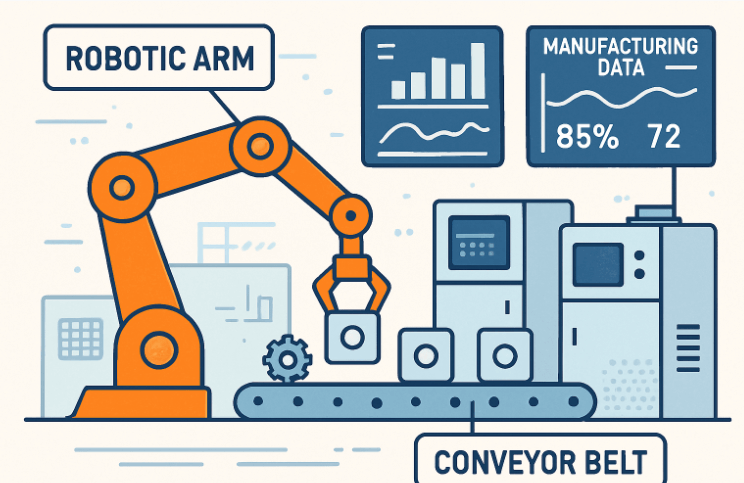

Autonomous Robotics in Assembly

The adoption of autonomous robotics in assembly lines is rapidly transforming the manufacturing landscape. These robotic systems are designed to perform repetitive, precise tasks without human intervention, dramatically improving throughput and reducing the risk of error.

According to a study from Stanford University, newly developed algorithms can manage fleets of autonomous robots, improving their coordination and adaptability during complex assembly operations. This paradigm shift allows production lines to transition from traditional rigid setups to dynamic, customizable processes that can more easily adapt to product variations and shifting order volumes.

The increased use of collaborative robots (cobots) has also enabled businesses to integrate automation without requiring massive infrastructure overhauls, supporting a blended workforce and fostering a culture of continuous improvement.

Delayed Building Block Supply

In traditional manufacturing, a continuous flow of parts is often considered essential for steady output. However, groundbreaking research from Ludwig Maximilian University of Munich shows that delaying the supply of building blocks can actually improve the efficiency of self-assembly processes in complex systems.

By slowing the resupply rate, manufacturers can reduce the formation of too many assembly nuclei at once, allowing partially completed structures to mature before new components are introduced. This approach not only enhances the quality of final assemblies but also minimizes waste and rework.

Especially in micro-assembly and pharmaceuticals, timed supply strategies have shown measurable improvements in both consistency and output quality. The counterintuitive nature of this technique challenges longstanding manufacturing assumptions and highlights the value of empirical experimentation in process optimization.

Automated Assembly Planning

Manually planning assembly sequences for complex products is both time-consuming and prone to error. Automated assembly planning algorithms address this challenge by determining the most efficient sequence of operations and calculating realistic motion paths for robots or human workers.

Innovative tools use computer-aided design (CAD) data to simulate thousands of component interactions, ensuring that each step in the assembly sequence is physically plausible and collision-free.

A recent breakthrough in algorithmic planning enables the simultaneous consideration of multiple assembly scenarios, significantly reducing the time required for engineers to prepare production runs for both low- and high-volume goods.

This approach ensures safer work environments and consistent product quality, reducing the risk of bottlenecks and costly downtime. Academic institutions like MIT are at the forefront of these developments, offering practical solutions for industrial engineers.

Synthetic Data for Visual Control

Effective quality control is central to maintaining high standards in manufacturing. Traditional visual assembly control systems require extensive training data, which can be costly and time-consuming to gather.

Synthetic data generation offers a scalable solution, using simulated environments and CAD-based renderings to train visual recognition algorithms without relying solely on real-world images.

This technique is particularly accessible for small and medium-sized enterprises (SMEs), enabling them to deploy advanced quality monitoring systems using digital twins and artificial intelligence.

By implementing synthetic data pipelines, manufacturers can accelerate the deployment of visual inspection solutions and rapidly iterate for continuous improvement, all while keeping their operational costs manageable.

This methodology is supported by a growing body of research in machine vision, as well as successful implementations in advanced electronics and automotive industries.

See also: Innovative Trends in Yacht Technology

Conclusion

Manufacturers that adopt innovative strategies, such as autonomous robotics, well-timed supply chain management, algorithm-driven planning, and synthetic data solutions, are well-positioned to thrive in an increasingly competitive global market.

These approaches enable greater efficiency, faster product turnarounds, and superior flexibility in responding to shifting customer needs. As industry leaders continue to set new benchmarks for operational excellence, the incorporation of these advanced techniques will serve as a cornerstone for sustainable growth and technological leadership.